BLOG

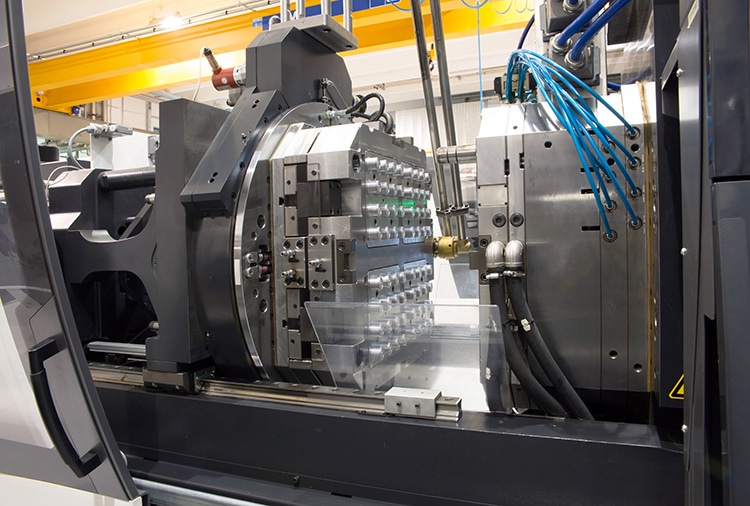

Mold, Release, Repeat: Chromium Coating as a Mold Release Agent for Injection Molding

Injection molding is a highly efficient method for the seamless demolding of products. This preferential manufacturing process produces vast quantities of uniform components with exact precision. From aerospace and automotive to medical devices and electronics, there...

Thin Dense Chrome for Pump Protection

Designed to process and treat the water that flows through sewers, wastewater treatment plants make it safe to return water to the environment. Different types of pumps are used throughout the treatment process to move the wastewater, and sometimes the treated water,...

Electrolizing® TDC

Unbeatable Protection From One of the “Big 7” What began as a single, groundbreaking coating is, today, multiple unique products—what we refer to as the “Big 7.” Each member of this exclusive club is formulated and optimized to meet different requirements. ...

Armoloy Bi-Protec®

Double Protection for Highly Corrosive Applications: Armoloy Bi-Protec® Metals used in parts, tools, and equipment are carefully selected for their specific characteristics. Chief among them in virtually every application are strength and durability. That is because...

Armoloy XADC®: A Perfect Partnership Between Chromium and Diamond

The title of a James Bond film from decades ago stated that Diamonds Are Forever. While we cannot claim that degree of longevity for metal parts, instruments, tools, or devices coated in Armoloy XADC®, we can state that it is a highly advanced electrodeposited coating...

Armoloy TDC®: The Foundation of the Big 7

Chromium coatings are so effective at protecting metal surfaces that it is easy to take them for granted. However, were it not for the work of a doctoral student named George Sargent, we might still be using tools, devices, and equipment that are highly vulnerable to...

Armoloy® Coating: Fixing a Costly Design Flaw with Precision

In an ideal world, product design, testing, and launch would go smoothly and as expected. Unfortunately, designers and manufacturers operate in the real world. And despite their best efforts, there are scenarios in which a product defect no one could have anticipated...

6 Ways Innovation Benefits Manufacturing Businesses

In manufacturing, sticking with what’s working is an easy and understandable approach. After all, innovation takes time, effort, and capital, all three of which are often in short supply. So, in the short term, the folksy advice that “if it ain’t broke, don’t fix it”...

Better Together: Industrial Lubricants and Chromium Coatings

Many systems and devices used in industrial and manufacturing processes require lubrication to operate correctly. The type of lubricant and how systems incorporate it varies based on the kind of device, the operating environment, and other factors. There are...

Understanding Lubrication, Bearings, and Chromium Coatings

Lubrication is one of the most critical factors in the performance of systems with metal surfaces that operate near or in contact with one another. Consequently, it is vital for everyone, from machine operators to business decision-makers, to understand what is...