Automation, Linear Motion &

Robotics Coatings

Optimize automation & robotics performance with Armoloy® coating. Lower friction, increased lubricity, anti-galling, high hardness & corrosion resistance.

- Lowers friction, smooth movement over articulating and rolling surfaces

- Increased Lubricity

- Anti Galling / Spalling / Fretting

- High hardness and wear resistance for extended product life

- Absolute Adhesion (will not chip flake or peel)

- Improved corrosion resistance, similar to 440 SS

- Even coating throughout critical geometries

- Thin, precise deposits do not affect geometry, weight, balance

- Attractive satin silver appearance for reduced glare

- Consistent and even appearance with no voids or rack marks (due to expertise with tooling)

- Can run dry for clean room applications

- Nodular surface will retain lubricants in wet applications

- Weld spatter resistant

- Chemical & Detergent Resistant

- 50% better in wear and corrosion over hard chrome

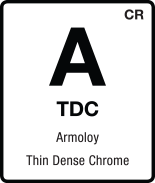

For over 20 years, Armoloy TDC® has been the premier coating for the automation, linear rail and robotics industry. The Armoloy TDC® coating lowers the coefficient of friction of bearing steels, for smoother movement over rolling surfaces, as well as imparting a much higher surface hardness, which improves wear resistance. In addition to reducing dust generation, the coating’s micro-nodular surface finish retains less lubricant for longer periods of time, resulting in a cleaner operation. Armoloy is also proven for dry lubricant applications.

The coating’s corrosion-resistance property on bearing steels is equivalent to 440C stainless steel, thus an Armoloy-coated guide or screw is a significantly more cost-effective option than fabricating the same component from stainless steel.

At a precise .0001/.0002″ deposit, Armoloy TDC® maintains machining tolerances and insures a smooth reassembly of the rolling element to the linear guide or ball screw. Armoloy TDC® is USDA approved and FDA compliant.

Testing completed by a major linear motion company showed the Armoloy TDC® coating to outperform typical hard chrome in both corrosion and endurance (wear) by nearly 50%. The test simulated 7 years of real-world use.

With many years experience in linear motion components, Armoloy of Illinois has perfected the science and the art of plating these components. 100% coverage, consistently even deposit, and a satin silver appearance free of rack marks is guaranteed, in addition to improved performance of the component.

Common applications include linear guides (rails) and blocks, balls crews and ball nuts, and geared racks and pinions.

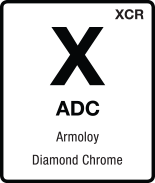

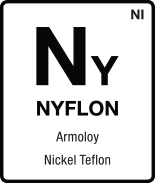

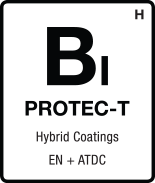

OUR COATINGS

A SOLUTION FOR EVERY APPLICATION