Aerospace Coatings

Key Benefits of the Armoloy Coatings for Aerospace Components

- Fully compliant to AMS 2438

- Thin even deposit, does not require secondary machining

- Thin deposit does not affect part tolerances, can be applied as low as .00005″

- Increased wear resistance, high surface hardness

- Cold process for no part distortion

- Enhance corrosion resistance (including atmospheric corrosion), corrosion resistance equal to 400 SS

- Extensive onsite testing and quality control

- Absolute bond to the base metal

- Performs in vacuum environments

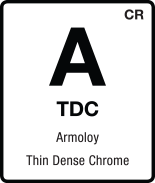

Armoloy TDC® is a metallic coating process designed for high precision applications required by the Aerospace industry. Our ability to control the process without affecting tight part tolerances makes it ideal for precision applications requiring increased wear, corrosion, and lubricity properties. The thin, hard coatings can be applied at even deposits ranging from .00005″ to .0006″ per side, with tolerances ranging from 0.00025″ to .00005″ per side. Please consult your Armoloy engineer for applications requiring heavier deposit thicknesses. Armoloy TDC® is considered a “cold” process that will not distort, anneal, or cause dimensional changes to your coated parts.

The Armoloy TDC® coating is fully compliant with AMS 2438, AMS 2460, and most customer-specific standards throughout the chrome coatings industry. Armoloy of Illinois operates processing tanks dedicated to AMS 2438 requirements and is capable of coating items to this standard up to 12 feet in length. Armoloy coatings can be applied to nearly all ferrous and non-ferrous base materials except for Aluminum and Titanium. Check with your Armoloy engineer for Aluminum coating options.

Armoloy of Illinois has years of experience meeting the rigorous demands of the industry’s most recognizable names. We work closely with each of our customers to establish requirements and custom-tailor solutions that best meet their needs. Armoloy of IL’s Quality control department employs extensive inspection and testing regimens, including 100% visual and deposit thickness verification, wear resistance, hardness, corrosion resistance, adhesion, and hydrogen embrittlement testing, and surface characteristic checks. Armoloy’s experienced staff will support all quality control and quality assurance initiatives required for your project, including FAI, PPAP, manufacturing and quality plans, controls plans, FMEA’s, gage R&R’s, and more.

Typical applications in the Aerospace industry include:

- Valves

- Bearings

- Landing Gear

- Rods/Shafts

- Pistons

- Transmission Components (gears, pinions, splines)

- Safety Devices (latches, pivot pins)

- Auxiliary systems

OUR COATINGS

A SOLUTION FOR EVERY APPLICATION