Oil & Gas Coatings

KEY BENEFITS:

- Increased abrasion resistance and component life

- Improved corrosion and erosion resistance

- Improved lubricity, low coefficient of friction from improved material flow

- Results in long service life of product

- Anti galling, Armoloy TDC® can be used as sacrificial between similar metals and can be run against itself for improved lubricity

- High effective temperature range, -400°F to 1500°F for extreme hot/cold applications

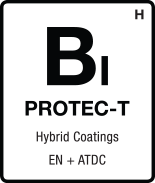

- Bi-Protec® excels in highly corrosive and abrasive environments

In the field of oil and gas drilling and extraction, the Armoloy coatings are ideally suited for components operating in corrosive downhole environments. The coatings’ high corrosion and wear resistance allows longer equipment run times and fewer expensive repairs, resulting in decreased downtime.

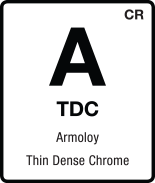

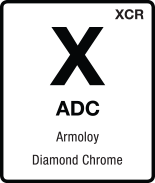

The Armoloy coating can be stripped from the substrate material and recoated almost indefinitely, helping to avoid costly component replacement. Worn components that have experienced material loss or deformation can also be coated to extend useful product life. Highly chemical resistant, Armoloy TDC® and XADC® resist most chemicals with the exception of sulfuric and hydrochloric acid.

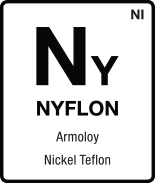

In addition to protection from corrosion and wear, the unique surface properties of the Armoloy coating can also improve media flow rates due to the reduced friction at the surface. Improvements of up to 10% in flow have been realized in application. By including a sub layer of electroless nickel under the Armoloy coating, the Bi-Protec® coating increases corrosion resistance dramatically.

Armoloy of Illinois serves those companies engaged in drilling both onshore and offshore.

Common applications include:

- seals, valves, rods, pistons, pumps, rotating elements, bushings, and sleeves

OUR COATINGS

A SOLUTION FOR EVERY APPLICATION