Food Processing & Packaging

Coatings

Key Benefits of the Armoloy Coatings

- USDA approved and FDA compliant for use with food applications.

- Corrosion resistance is equivalent to 440 SS.

- Enhances cleaning and sanitary operations.

- Chemical resistant to most cleaners used for maintenance and equipment washdown.

- Absolute bond to base metal will not flake chip or peel.

- Nodular micro surface reduces friction for improved lubricity and release.

- Can run dry with excellent lubricity in cleanroom applications.

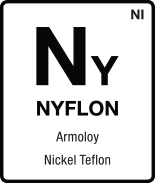

- Nyflon® for the lowest coefficient of friction and release.

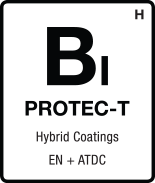

- Electroless Nickel® for best corrosion resistance.

- Can withstand extreme hot and cold temperatures, temperature for ArmoloyTDC® /XADC® in excess of 1300F.

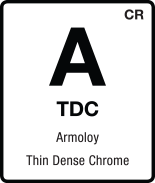

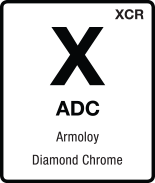

Armoloy TDC®/XADC® have been applied to food-processing and food-packaging components for their unique combination of wear resistance and corrosion resistance. The Armoloy coating’s absolute bond and stainless steel against stainless steel galling protection provide the ultimate in processed product purity, knowing the coating will not chip, flake, or peel.

Armoloy TDC® and XADC® (coatings) are approved for food contact applications by the USDA and considered safe for food contact by the FDA. The coatings can withstand temperatures above 1200˚F and are not affected by thermo-shock when cooled.

The coatings’ resistance to corrosion caused by daily wash-downs aids in reducing maintenance downtime. Applying the coatings to stainless steel results in magnitudes of corrosion resistance much greater than either stainless steel or coated tool steel, and excellent for galling protection.

Typical applications include bearings, chutes, pumps, linear rails, cutting tools, and machined packaging-line components.

OUR COATINGS

A SOLUTION FOR EVERY APPLICATION